We are committed to ensuring that risks associated with the work Falkirk Council performs are well managed to help ensure the safety of our employees and those affected by our work. By eliminating workplace hazards and reducing health and safety risks associated with our work we will reduce and prevent work related injuries and ill-health.

This How To forms part of Falkirk Council's safety management system and applies to all Council work activities and workplaces.

Managing Health and Safety risks

Applying sound risk management principles to work activities allows the Council to protect the health and safety of its employees and to identify opportunities for improving the work the Council undertakes.

Risk Profiling

Services are required to maintain a profile of the key health and safety risks it's work exposes employees and other to. As part of the profile, key health and safety risks (such as vibration, occupational violence, manual handling, etc) will be identified, risk rated and have relevant legislation and control strategies for the Service recorded against each risk. This profile should be reviewed regularly by the Service in conjunction with the Health, Safety and Wellbeing team and used to inform decision making by the Service.

Health and Safety Action Plan

Each Service will maintain a Health and Safety Action Plan which outlines actions taken to either address health and safety risks within the Service or take advantage of identified opportunities for improvement regarding health and safety.

The relevant Service Director has overall accountability for the delivery of this action plan, however they should devolve responsibility for actions as appropriate within their Service.

This action plan must explicitly state the nature of the action being undertaken, expected timeframes for completion and identify responsible persons to complete actions.

Service Health and Safety Action Plans should be stored and maintained in an accessible place. They should be made available and communicated to managers and employees within the Service.

Health and Safety Risk Assessments

Falkirk Council has a responsibility to assess the risks that it's work poses to both employees and non-employees. In order to determine what these risks are and the best way of controlling them work activities must be risk assessed. These assessments relates to risks stemming from Council work activities. Some risk assessments are outside the scope of this guide:

- Person centred risk assessments

- Risk assessments required by specific health and safety regulations (noise, manual handling). Specific guidance on this risk assessments will be provided separately.

- Non health and safety risk assessments

In instances where health and safety regulations required specific risk assessments (such as noise or manual handling) the risk should be initially identified with the work activity risk assessment and then a further, specific risk assessment completed that complies with regulatory requirements.

All health and safety risk assessments must be recorded on the Council's online health and safety system.

Quarterly Health and Safety Risk Assurance Statement

All Services are required to complete a Quarterly Risk Assurance Statement for the review of the Health & Safety Operational Risk. When undertaking this review Services must ensure the following are undertaking to inform the review process:

- Consider the Service's progress against their Health and Safety Action Plan

- Review their selected Health and Safety Key Performance Indicators

- Consult with the Senior Health, Safety & Wellbeing Advisor prior to completing the review

Work Activity Risk Assessments

All work activities that Services undertake should be risk assessed in order to ensure that risks to employees and members of the public health and safety are adequately controlled.

Risk assessments should be undertaken in a collaborative manner in conjunction with employees and Trade Union representatives. Services should ensure that when undertaking a risk assessment the people involved are competent to undertake the risk assessment. At a minimum there should be:

- Adequate technical knowledge of the work activity being undertaken

- At least one risk assessor who has completed the risk assessment Olle module

- Adequate representation of the relevant workforce by engaging with Trade Union representatives and employees as necessary

All work activity risk assessments should be reviewed on a regular basis as determined by the highest risk rating within the risk assessment. This rating is determined using the risk matrix in Appendix 2:

| Highest rated risk |

Minimum review frequency |

| Very high |

Every 3 months |

| High |

Annually |

| Medium |

Every 2 years |

| Low |

Every 3 years |

In addition to the requirement to review work activity risk assessments in line with the minimum review frequency above, risk assessments should be reviewed and updated where:

- There is a change in how the work activity is undertaken. This could include changes to the work equipment or tools that are used, changes in the work environment or people who perform the work activity

- There are new hazards identified or previously unidentified hazards that are associated with the work activity

When work activity risk assessments are review and updated because of this the hazards should be risk assessed in the same manner as existing hazards.

Identifying workplace hazards and risks

Understanding the workplace hazards associated with the work activities Services undertake is fundamental to appropriately managing the health and safety risks they pose to employees and others.

A hazard is something within the workplace with the potential to cause either injury and ill health. In the context of this guide, injury and ill health results in an adverse effect on the physical, mental or cognitive condition of an individual. Hazards interact with individuals through either a hazardous event(s) (someone tripping on broken flagstones) or exposure (someone coming into contact with an irritating chemical).

A list of common workplace hazards and their definitions is included below. This list is included in the risk assessment module of the EVOTIX Assure module.

Once hazards related to a work activity are identified the occupational health and safety risk should be assessed with the existing control measures in place (or no control measures if none are present). The occupational health and safety risk is the combination of the likelihood of a work-related hazardous event(s) or exposure and the severity of injury and ill health that can be caused by the event or exposure.

The risk matrix is contained within the EVOTIX Assure module and must be used for assessing work related risks to health and safety.

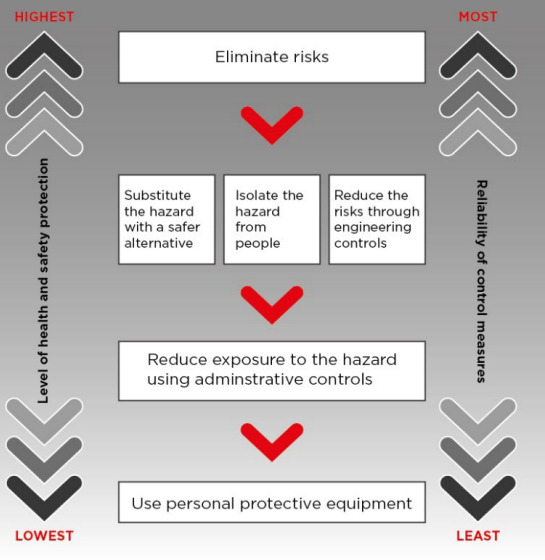

Eliminating workplace hazards and reducing risks

Once workplace hazards are identified and risk assessed, control measures should be selected and implemented to reduce and control the risk of injury and ill health so far as is reasonably practicable. To do this the Hierarchy of Control should be implemented to identify the control measures with the most effectiveness in eliminating or reducing this risk.

When determining if something is reasonably practicable to individuals involved in undertaking a risk assessment they should weigh the risk of injury and/or ill health to employees and non-employees against the means required to avert the risk in resources, time or money). This responsibility is discharged where it can be shown that there is a gross disproportion between the risk of injury or ill health and the measures required to control it.

This is not a process of balancing the costs and benefits of control measures, but of adopting control measures except in situations where they involve greatly disproportionate sacrifices. Extreme examples might be:

- To spend £1m to prevent 5 staff suffering bruised knees is obviously grossly disproportionate; but

- To spend £1m to prevent a major explosion capable of killing 150 people is obviously proportionate.

Work areas must always aim to eliminate the risk, which is the most effective control. If this is not reasonably practicable, they must minimise the risk by working through the other alternatives in the hierarchy.

The lower levels in the hierarchy are less effective because controls that change the hazard or minimise exposure to the hazard can only minimise the risk. You cannot eliminate the risk without eliminating the hazard.

Administrative controls and personal protective equipment (PPE) are the least effective at minimising risk because they do not control the hazard at the source and rely on human behaviour and supervision.

Elimination

The most effective control measure involves eliminating the hazard and associated risk. The best way to do this is by, firstly, not introducing the hazard into the workplace. For example, you can eliminate the risk of a fall from height by doing the work at ground level.

Eliminating hazards is often cheaper and more practical to achieve at the design or planning stage of a product, process or place used for work. In these early phases, there is greater scope to design out hazards or incorporate risk control measures that are compatible with the original design and functional requirements. For example, not using a noisy machine will be more effective than providing employees with personal hearing protectors.

Risks can also be eliminated by removing an existing hazard, for example, by removing trip hazards on the floor, disposing of unwanted chemicals, or not working in an isolated or remote area.

It may not be reasonably practicable to eliminate a hazard if doing so means that you cannot make the end product or deliver the service. If the hazard cannot be eliminated, then it must be minimised so far as is reasonably practicable.

Substitution, isolation and engineering controls

If it is not reasonably practicable to eliminate the hazards and associated risks, these should be minimised by using one or more of the following approaches, so far as is reasonably practicable.

Substitute the hazard with something safer

For instance, replace solvent-based paints with water-based ones or allow employees to have more control of line speed instead of pacing line work by computer.

Isolate the hazard from people

This involves physically separating the source of harm from people by distance or using barriers. For instance, install guardrails around exposed edges and holes in floors; use remote control systems to operate machinery; store chemicals in a fume cabinet; place barriers between workers and customers where there is a risk of assault.

Use engineering controls

An engineering control is a control measure that is physical in nature, including a mechanical device or process. For instance:

- use mechanical devices such as trolleys or hoists to move heavy loads

- place guards around moving parts of machinery; install residual current devices (electrical safety switches)

- set work rates on a production line to reduce fatigue

- install sound dampening measures to reduce exposure to unpleasant or hazardous noise.

Administrative controls

If risks remain, they must be minimised by implementing administrative controls, so far as is reasonably practicable. Administrative controls include work methods or procedures that are designed to minimise exposure to a hazard as well as the information, training and instruction needed to ensure workers can work safely. For instance:

- develop procedures on how to operate machinery safely

- provide training and support to managers and workers to identify and manage health and safety risks

- implement anti-bullying policies

- limit exposure time to a hazardous task

- use signs to warn people of a hazard

Some administrative measures will be necessary to ensure substitution, isolation and engineering controls are implemented effectively, for example, following safe work procedures when using equipment.

Personal Protective Equipment (PPE)

Any remaining risks must be minimised with suitable PPE. PPE limits exposure to the harmful effects of a hazard but only if workers wear and use the PPE correctly.

Examples of PPE include:

- ear defenders

- respirators

- face masks

- hard hats

- gloves

- aprons

- protective eyewear

Roles & responsibilities

In addition to their responsibilities under the Council's Health & Safety Policy, certain employees have the following responsibilities regarding the implementation of this How To guide.

Service Directors, Heads of Service and Chief Officers

Service Directors, Heads of Service and Chief Officers are responsible for ensuring the health and safety of all employees and others in their respective service areas Service Directors, Heads of Service and Chief Officers will:

- ensure all employees are aware of this document

- ensure that adequate resources are made available within their Services to enable the implementation of this document

- maintain and update their respective Service's H&S Risk Profile

- maintain, update and communicate their Service's H&S Action Plan to managers and employees

- ensure the quarterly risk assurance statements for health and safety are undertaken appropriately with the consultation of the Health, Safety & Wellbeing team.

Service Unit Managers & Head Teachers

All Head Teachers and managers who have operational responsibility for other employees or for systems and procedures of work will be responsible for ensuring that:

- work activities within their respective work areas are adequately risk assessed

- employees within their respective work areas are aware and understand the outcomes of these risk assessments and ensure employees have access to these risk assessments. This includes the requirement to use identified work equipment and PPE, as well as following identified procedures and training.

- ensure that this document is implemented within their respective work areas

- Where there are material changes to risk assessments (normally after a review is undertaken), Service Unit Managers and Head Teachers will ensure their employees are made aware of the changes and have access to the updated risk assessments

- ensure all employees are aware of this document

- Contribute to the development of risk assessments within their work areas

- Ensure employees and Trade Unions are consulted and engaged with during the risk assessment process

First Line Managers, Team Leaders, Supervisors & Charge-Hands

These employees will have responsibility for implementing, monitoring and reviewing systems of work to achieve good safety management with the Council.

These individuals will lead by example and be champions for Health and Safety within their work environment and are responsible for:

- ensuring the requirements of risk assessments are implemented within their respective work areas and shared with new and existing employees

- contributing to the development of risk assessments within their work areas

- ensuring employees and Trade Unions are consulted and engaged with during the risk assessment process

- ensuring all employees are aware of this guide

Trade Union Representatives

Trade Union representatives will have responsibility for assisting with the development, implementation and monitoring of health and safety policies and procedures.

They will do this by:

- contributing to the development of risk assessments within their work areas

- undertaking the responsibilities as listed below for employees

- providing adequate representation of the relevant workforce in areas for the development and implementation of risk assessments

Employees

In order to create a positive and effective culture in regard to health & safety it is vital that all employees of Falkirk Council contribute positively to the successful management of health & safety. Employees will:

- contribute to the development of risk assessments within their respective work areas

- ensure they read and understand the contents of risk assessments. Employees who need further assistance in understanding how the risk assessment applies to their work must seek assistance from their line manager.

- work in accordance with the requirements of relevant risk assessments and associated instruction, safe working methods and training received

- alert line managers to unsafe practices, conditions or incidents of concern that may trigger the review of a risk assessment

Health, Safety & Wellbeing Team

The Health, Safety & Wellbeing team is responsible for maintaining the Council's safety management system. They will assist Services in developing their risk assessments by:

- providing technical advice where appropriate and within their respective competence

- maintain the EVOTIX Assure system

- develop tools and guidance to assist Services in managing work related risks and hazards

Safety Management Group

The Council's Safety Management Group consists of Trade Union and Council representation. It will assist in the implementation of this guide and its ongoing development by:

- assisting the Health, Safety & Wellbeing team on further developing the EVOTIX Assure system within the Council

- agreeing updates to the risk assessment process and requirements for implementing this policy outwith the existing policy process for the Council

- undertaking an Annual Governance Self-Assessment regarding the operation of the group

Common workplace hazards

| Workplace hazard |

Details |

| Asbestos |

A controlled or uncontrolled exposure to an asbestos containing material (ACM) |

| Confined spaces |

A confined space is one which is both enclosed or largely enclosed and has a reasonably foreseeable specified risk to workers of:

- fire

- explosion

- loss of consciousness

- asphyxiation

- drowning

It may be small and restrictive for the worker or it could be far larger such as a grain storage silo with hundreds of cubic metre capacity. |

| Display Screen Equipment (DSE) |

DSE are devices or equipment that have an alphanumeric or graphic display screen and includes display screens, laptops, touch screens and other similar devices. |

| Electricity |

Contact with live sources of electricity such as overhead powerlines, electrical systems in buildings or portable appliances. |

| Fire |

Exposure to a heat source or live fire such as welding, uncontrolled fire in the workplace can cause burns, smoke inhalation or property damage. |

| Hazardous substances |

Exposure to hazardous substances such as chemicals or biological materials.

In some situations a specific Control of Substance Hazardous to Health (COSHH) risk assessment may be required. Please consult the Health, Safety & Wellbeing team. |

| Lone working |

Employees working by themselves without close or immediate supervision. This includes employees working from home. |

| Manual handling |

Manual handling means transporting or supporting a load by hand or bodily force. It includes lifting, lowering, pushing, pulling, moving or carrying a load/person.

In some situations a specific manual handling risk assessment may be required. Please refer to the Council's Manual Handling Policy (PDF, 144KB). |

| Noise |

Exposure to excessive noise.

In some situations a specific noise risk assessment may be required. Please refer to the Council's Control of Noise at Work Policy (PDF, 141KB). |

| Security |

Breaches in security measures resulting in an unauthorised person accessing a workplace. |

| Slips, trips & falls |

Loss of balance on surface resulting in a person slip/trip/fall can result from uneven work surfaces or obstructions. |

| Stress (work related) |

The adverse reaction people have to excessive pressures or other types of work related demands placed on them. |

| Vibration |

Exposure to vibrating equipment (either hand arm or whole body)

In some situations a specific vibration risk assessment may be required. Please refer to How to manage vibrations at work. |

| Violence (work related) |

Any incident in which a person is abused, threatened or assaulted in circumstances relating to their work. |

| Work environment |

Characteristics of the physical working environment that may lead to ill health and injury. |

| Work equipment |

Failing to effectively manage work equipment in a way that means there is an increased risk of injury or ill health occurring or failing to meet statutory obligations such as undertaking thorough examinations. |

| Working at height |

Work in any place where, if precautions were not taken, a person could fall a distance or drop an object liable to cause personal injury. You are working at height if you: work above ground/floor level. |

H&S Risk Assessment Risk Matrix

This risk matrix and associated definitions should be used for assessing the health and safety risks of work activities within the EVOTIX Assure Risk module. When applying this risk matrix, assessors should select appropriate likelihood and severity rating for the risk they have identified for relevant hazards.

Identified risks should be managed to reduce the risk to a level where reasonably practicable.

Likelihood

The likelihood of the identified risk occurring.

| Likelihood |

Details |

| Almost certain |

Expected to occur in most circumstances |

| Likely |

Will probably occur in most circumstances |

| Possible |

Might occur occasionally |

| Unlikely |

Could occur sometime but not expected |

| Rare |

May occur only in exceptional circumstances |

Severity

The severity of the identified risk.

| Severity level |

Details |

| Negligible |

No injury/illness or first aid treatment only. No time lost. |

| Minor |

Medical treatment required for injury. A full work shift has not been lost. |

| Moderate |

Lost time injury or illness without permanent impairment. |

| Major |

Serious injury or illness with permanent impairment. |

| Extreme |

A loss of life. |

Risk matrix

| Likelihood |

Severity |

| Negligible |

Minor |

Moderate |

Major |

Extreme |

| Almost certain |

Medium |

Medium |

High |

Very High |

Very High |

| Likely |

Medium |

Medium |

High |

Very High |

Very High |

| Possible |

Low |

Medium |

High |

High |

Very High |

| Unlikely |

Low |

Medium |

Medium |

Medium |

High |

| Rare |

Low |

Low |

Low |

Medium |

High |

Risk response

Identified risks should be managed to reduce the risk to a level that is reasonably practicable and in accordance with the table below.

| Risk rating |

Response to the risk |

| Very high |

Cease work activity and consult the Health, Safety and Wellbeing Team.

As soon as possible (and within one month) implement additional control measures for work activity.

3 monthly formal review by relevant manager and ongoing monitoring of work activity in work area until effectively managed. This includes updating the risk assessment action plan. |

| High |

Within one month implement additional control measures for activity. Annual review by risk owner until effectively managed. This includes updating the risk assessment action plan.

Consider for further analysis and control measures as part of ongoing reviews. |

| Medium |

Consider for further analysis and control measures as part of ongoing reviews.

Review every 2 years if not Very High or High risks within risk assessment. |

| Low |

Maintain effectiveness of current controls and manage by routine procedures.

Review every 3 years if no Very High, High or Medium risks within risk assessment.

|