Exposure to vibration at work is a hazard for employees in many industries and occupations. It comes from using work equipment like powered hand tools, grass cutting equipment, road breakers or chainsaws or by holding materials being processed by machines like pedestal grinders.We provide a range of services that use vibrating equipment.

Regular and frequent exposure to vibration can cause permanent health effects. This is most likely when using vibrating equipment and tools is a regular part of a person's job. Occasional use is not likely to cause ill health.

There are 2 ways employees can be affected by vibration:

-

Hand-arm vibration (HAV) is transmitted from work equipment into an employee's hands and arms.

-

Whole-body vibration (WBV) is transmitted to the body while sitting/standing on work equipment or vehicles.

To effectively manage the risks from vibration we will:

- assess the risks to anyone whose work involves the use of vibrating equipment

- eliminate the risks from exposure to vibration at work where reasonably practicable

- ensure systems are in place to manage work activities that could expose employees to vibration

- provide employees with appropriate information, instruction and training to safeguard themselves and others

- provide health surveillance for employees whose health may be at risk from their exposure to vibration at work

Risk assessment

Line Managers will ensure a current risk assessment is available for all work activities in line with the Council's Risk Management by Risk Assessment policy:

If a risk assessment is not available, the Line Manager will complete one before the work activity can be allowed to start.

We have an over-arching duty to remove any exposure to vibration wherever reasonably practicable. If the risk assessment shows that employees are likely to be exposed to vibration, Service Managers are responsible for ensuring alternative ways of working are identified to limit any unnecessary exposure to vibrating equipment. They will involve Line Managers, Supervisors and employees in this process.

If it's not reasonably practicable to eliminate exposure to vibrating equipment completely Line Managers will also carry out a separate vibration risk assessment. It will highlight where there could be a risk to employees' health from their use of vibrating equipment.

When carrying out the vibration risk assessment, Line Managers will:

-

observe the work activity and list the individual tasks involved. List all steps in the activity, including those that don't involve any vibrating equipment

-

identify all items of vibrating equipment used and their vibration magnitude. If measured vibrations magnitudes are not available published figures can be used (see Sources of vibration magnitude data)

-

estimate the trigger time for each task involving vibrating equipment. The length of time that the equipment is actually operating and its operator is exposed to vibration. Personal monitoring equipment can be used to estimate trigger time

-

calculate the vibration exposure points for the work activity from the vibration magnitude and trigger time using the HSE's online calculator. The calculator will provide an indication of the expected exposure points and the length of time equipment can be used before reaching an action value (see Exposure action and limit values). If the activity uses multiple vibrating tools, they should all be input into the calculator to calculate the total vibration exposure points for the work activity. The HSE's HAV and WBV calculators can be accessed below:

-

identify and record the control measures needed to reduce vibration exposure to as low a level as is reasonably practicable (see Management controls)

For help in completing vibration risk assessments contact:

Employees will notify their Line Manager of any new hazards encountered during any work activity or if they believe the controls measures in place no longer adequately manage the risks. Line Managers will ensure all employees have access to and understand the risk assessments.

Line Managers will review risk assessments at least annually or following:

- a significant change to a work activity, the working environment or equipment

- change in regulatory or other duties

- an incident, near miss or diagnosis of a vibration related condition in an employee

- a report that a risk assessment doesn't adequately reflect the work activity

This will include a review of the vibration magnitudes and trigger times.

Sources of vibration magnitude data

A range of sources of information on vibration magnitudes is available to use. These include:

- measurements made in your own workplace

- external contractor

- HSE publications

- manufacturers figures in the equipment handbook

- internet databases

- trade associations and research organisations

Where possible vibration magnitudes measured in the workplace should be used. Measurements should only be made using suitable, calibrated equipment by an employee competent in its use and in the evaluation of the results. If a competent employee is not available an external contractor can be used.

Where it has not been practical to measure vibration magnitudes, published data can be used. Examples of vibration magnitudes measured during normal uses of common machines are available in Appendix 3 of the HSE publication L140: Hand Arm Vibration (PDF, 6MB).

If an appropriate vibration magnitude for your equipment isn't available in L140, you should seek out another reliable source from the options listed above.

The published vibration magnitudes you use must be appropriate to your work activities and the conditions in which the equipment will be used. Vibration data is collected for many purposes and isn't always suitable for estimating daily vibration exposures. You can increase your confidence in the quality or relevance of available vibration magnitude information by obtaining the most up-to-date information and comparing data from at least two sources. It's important that the vibration magnitude figures used do not underestimate the vibration exposure. If you are uncertain about the available sources of vibration magnitude data you should contact:

Exposure Action and Limit Values

The Exposure Action Value (EAV) and Exposure Limit Value (ELV) are limits set for daily vibration exposure.

It's reasonable to assume that the EAV or ELV is likely to be exceeded if risk assessments show the total vibration points for a working day is:

| Daily exposure measure |

Hand Arm Vibration |

Whole Body Vibration |

| Exposure Action Value |

84 |

84 |

| Exposure Limit Value |

334 |

441 |

The risk assessment for a work activity will indicate whether action is needed to protect employees who are using vibrating equipment; the higher the exposure points, the greater the risk to employees. However, activities can't be looked at in isolation. Line Managers will take account of workloads and identify where activities are likely be combined over a working day.

If an activity, or combination of activities in a working day, is likely to expose any individual to vibration at or above the EAV, the Line Manager will ensure the relevant controls listed in the risk assessment are put in place to reduce exposure to as low a level as is reasonably practicable (see Management controls).

The ELV must not be exceeded. If a risk assessment shows that an activity is likely to expose any individual to vibration at or above the ELV work activities must not begin until the vibration exposure can be reduced. Line Managers will review the risk assessment(s) to identify the reason for the ELV being reached and notify the relevant Service Manager. Service Managers will introduce controls to reduce exposure to as low a level as is reasonably practicable (see Management controls). The Line Manager will update the risk assessment to show the controls required. Controls should be adequate to ensure the ELV is not reached.

If an activity is considered essential to Council operations but exceeds the ELV contact the Health, Safety and Wellbeing Team for further advice.

Review

Line Managers will review risk assessments:

- if there has been a significant change to vibration related activities and/or equipment

- if there has been a change in regulatory or other duties

- if there is any reason to suspect that the risk assessments are no longer valid

- following the diagnosis of a vibration related injury

- at least annually

Line Managers will ensure all employees are informed of and understand any changes to the risk assessment.

Management controls

Service Managers are responsible for ensuring a range of suitable control measures are available to reduce the risks from exposure to vibration to as low a level as is reasonably practicable. These include:

- equipment selection and purchasing policy

- planned preventative maintenance

- task management

- equipment tagging

- monitoring

- personal protective equipment

- information, instruction and training

It's important to note that exposures below the EAV are not risk-free. Improvements to working practices should not stop once exposure is reduced to 84 points.

If further reductions can be achieved at a reasonable cost and effort then they should be implemented. Before deciding whether measures to reduce exposure to vibration are not reasonably practicable you should contact:

Equipment selection and purchasing policy

Work equipment must be suitable for the task. While the supplier can provide information about the vibration magnitude of their products it's recommended that new tools are tested prior to purchase. Team Managers will obtain a demonstration model from the supplier or hire one in order that they can be trialled in the conditions they will be used. An assessment of the vibration exposure should be carried out (see Risk assessment).

The efficiency of equipment should be considered when assessing their suitability. While some models can emit lower levels of vibration than others, they may be less efficient and tasks could take longer to complete. This could potentially increase vibration exposure. Equally, equipment may also be too powerful for their intended use. This could also result in unnecessarily high vibration exposures.

The same principals apply to the selection of equipment that is hired or leased. No equipment should be used until a vibration risk assessment has been carried out.

Planned preventative maintenance

The performance of vibrating equipment will naturally deteriorate with use. Over time this deterioration can lead to increases in vibration. To minimise the effects of this deterioration Service Managers will ensure that a programme of planned preventative maintenance is in place for all work equipment. The programme will ensure equipment is inspected and serviced on a regular basis in line with the manufacturer's recommendations.

As part of the maintenance programme the vibration magnitude of the equipment should be tested and the tag updated (see Equipment tagging). Line Managers will check that an updated tag is displayed before equipment is returned to use.

Employees are also responsible for reporting any deterioration in the performance of equipment used to their Line Manager. This should be reported as soon as it is identified and employees should not wait until the end of the working day or until the equipment fails. Equipment will be taken out of use for evaluation and repair or replacement as required.

Consumable components like drill bits, grinding wheels, cutting heads and abrasive papers can have a significant impact on the efficiency of equipment. It's important that consumables are replaced as required. Line managers will ensure the correct consumables are available and used by employees.

Service Managers will ensure that a process is in place to assess the continued suitability of equipment. As equipment reaches the end of its working life it should be removed from use for disposal and replaced (see Equipment selection and purchasing policy).

Task management

Vibration risk assessments will provide an indication of the exposure points likely to be experienced for each work activity. They will also provide an indication of the length of time equipment can be used before the EAV and ELV are reached (see Risk assessment).

Each piece of equipment will also be tagged to give employees and line managers a visual indication of the vibration points that will be accumulated (see Equipment tagging).

Line Managers will ensure that tasks are allocated to minimise individual employees' exposure points over the course of a working day. When allocating work to individuals, Line Managers will need to take account of the total exposure points from all activities. If any individual employee's exposure is likely to reach or exceed the EAV the Line Manager will review the work allocation to check if exposure:

Line Managers are responsible for organising workloads to ensure that no employee can accrue enough exposure points over a working day to exceed the ELV. Employees must be aware of the limits and controls measures detailed in the risk assessments and notify their Line Manager if they suspect their daily workload is likely to reach or exceed the ELV. If an individual's workload is likely to reach or exceed the ELV work activities must not be carried out until their vibration exposure can be reduced.

Line Managers will review the risk assessment(s) to identify the reason for the ELV being reached and ensure the ELV is not reached again (see Risk assessment).

When allocating work activities, Line Managers will take account of any employee whose health is likely to be particularly at risk from vibration; like employees who have been diagnosed with a vibration related condition or a young person. The workload of employees whose vibration exposure has been restricted on the advice of Occupational Health should be managed to ensure their personal limit is not likely to be exceeded. These employees are also required to use personal monitoring equipment to ensure they do not exceed their personal limit (see Monitoring).

Work activities can combine tasks that involve the use of vibrating equipment with those that don't. Regularly switching between these tasks can be used to limit the accumulation of exposure points.

Line Managers will ensure that safe systems of work and control measures are in place and followed.

Equipment tagging

Line Managers will ensure all vibrating equipment is tagged to show:

-

the vibration magnitude of the equipment

-

the number of exposure points that will be accumulated from using it

-

the date the vibration magnitude was tested

This will help Employees to manage their accumulation of exposure points. Tags will be colour coded to provide a simple indication of the risks from the use of the equipment:

| Tag colour |

Vibration magnitude |

Description |

| Green |

0m/s2 - 2.5m/s2 |

It is unlikely that the EAV will be reached or exceeded over the course of a normal working day using any combination of tools or equipment that have a GREEN tag. |

| Amber |

2.5m/s2 - 5m/s2 |

Depending on the vibration magnitude the EAV could be exceeded after as little as 2 hours of trigger time. It is unlikely that the ELV would be exceeded over the course of a normal working day using any combination of tools that have AMBER and GREEN tags. If you believe the EAV is likely to be exceeded you should notify your Line Manager who will review the relevant risk assessments. |

| Red |

5m/s2 |

Depending on the vibration magnitude the EAV could be exceeded after as little as 15 minutes trigger time and it is likely that the ELV could be exceeded if the equipment is used for any more than short duration tasks. The use of any RED tagged equipment or combination of RED, AMBER and GREEN tagged equipment should be closely monitored to ensure the ELV isn't exceeded (see Monitoring). |

Employees must not use a piece of equipment unless it has a tag dated within the previous 12 months. Any employee finding equipment without a tag or with an expired tag should report it to their Line Manager. Their line manager will take the equipment out of use until the tag can be replaced or updated as required.

Monitoring

There is no requirement to use personal monitoring equipment to continually monitor exposure, with the following exceptions:

- employees whose vibration exposure has been restricted on the advice of Occupational Health (see Health surveillance)

- employees who use any red tagged equipment (see Equipment tagging)

Line Managers will ensure these employees use personal monitoring equipment to ensure their vibration exposure can be effectively managed over the course of a working day.

Line Managers will ensure that the alarm on the device is set for 80% of either:

- an individual's personal limit as advised by Occupational Health

- the ELV if employees are using red tagged equipment

Line Managers will ensure appropriate personal monitoring equipment is available to any employee who needs to use it.

If an employee reaches 80% of their set limit during their working day they should notify their Line Manager. The Line Manager will reorganise work activities to avoid the use of vibrating equipment for the rest of the working day.

Line Managers will review vibration exposure data from the personal monitoring devices weekly. If an employee's exposure regularly exceeds 80% of their respective limit value their Line Manager will review the employee's workload and implement additional control measures to further reduce exposure.

Personal protective equipment (PPE)

Low hand or body temperature increases the risks from the effects of vibration because of reduced blood circulation. Line Managers will ensure that employees are issued with and use appropriate clothing and gloves. Employees working in cold environments should have adequate access to warm, dry clothing; whether working outdoors or indoors.

Anti-vibration gloves are commercially available but can't be relied upon to provide protection against Hand-arm vibration. Anti-vibration gloves provide most protection against higher vibration frequencies; higher frequencies than the equipment currently being used. They must not be favoured over other management controls. Employees are however encouraged to wear gloves to keep their hands warm and reduce the risk of vibration related injury.

Training

Training employees in correct and safe working practices is essential in managing the risks from vibration. Line Managers will ensure a suitable training programme is in place for employees who are routinely exposed to vibration at work. As a minimum training should include an explanation of:

- vibration at work and the health risks to employees

- the risk assessment process

- the significant findings from risk assessments including the vibration exposures and how they relate to the Exposure Action and Limit Values

- the management controls and safe working practices in place to reduce exposure to as low a level as is reasonably practicable

- how to recognise the signs of vibration related conditions

- the health surveillance scheme and how it works

Line Managers will ensure training is provided on induction and refreshed:

- following any changes to the risk assessment

- at regular intervals depending on the risks from vibration

Health surveillance

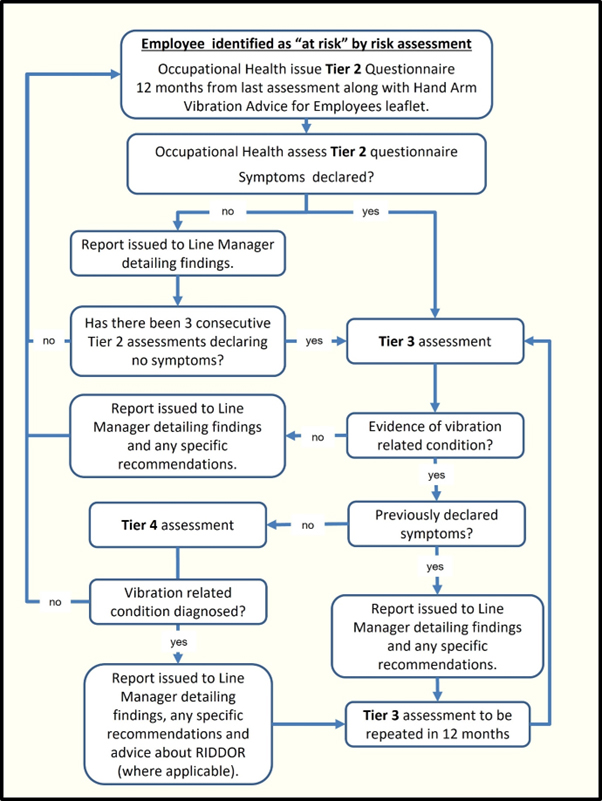

Health surveillance will be provided to any employee who is likely to be exposed to vibration levels at or above the EAV (see Risk assessment). The following tiered process is in place to monitor the health of employees who may be exposed to vibration through their work activities:

| Tier level |

Description |

| Tier 1 |

Pre-employment questionnaire to provide baseline assessment |

| Tier 2 |

Annual screening questionnaire |

| Tier 3 |

Face to face assessment by OH professional |

| Tier 4 |

Referral to an Occupation Physician for assessment and formal diagnosis |

| Tier 5 |

Use of standardised tests. Tier 5 is not required as part of routine health surveillance but may be recommended in some cases by the Occupational Physician where further assessment is required. |

For new employees, there are a number of checks which must be completed as part of the recruitment process (see How to carry out recruitment checks).

Once the preferred candidate has been selected, the Recruiting Manager will issue a Tier 1 questionnaire along with the Baseline Health Questionnaire. This will provide an opportunity to record any existing vibration related conditions. If the preferred candidate declares any vibration related symptoms the Recruiting Manager will refer them to Occupational Health for a Tier 3 Assessment. Occupational Health will advise the Recruiting Manager on the preferred candidate's fitness for the role along with any specific recommendations. The Recruiting Manager will contact the HR Business Partner for advice and guidance before deciding whether to make a formal offer of employment based on the outcome of this initial Tier 3 Assessment.

Recruiting Managers will ensure Occupational Health are provided with information the type of work undertaken and risks involved for all vacancies advertised.

Following employment any employee who is likely to be exposed to vibration levels at or above the EAV will be provided with regular health surveillance.

Employees must also immediately report any symptoms of vibration related conditions to their Line Manager. The Line Manager will then organise a referral to Occupational Health for a Tier 3 Assessment. Early signs and symptoms include:

- tingling and numbness in the fingers, this can also disturb sleep

- not being able to feel things with your fingers

- loss of strength in the hands possibly being unable to pick up or hold heavy objects

- fingertips may go white then red in the cold and wet and painful when they warm up

Line Managers will also ensure that health surveillance is provided for employees who use vibrating equipment but are not currently classed as being at risk from vibration if they've notified their Line Manager they suffer from:

- existing HAVS or other diseases of the hands, arms, wrists or shoulders

- conditions affecting blood circulation, like Raynaud's disease or carpal tunnel syndrome

WBV has been linked to persistent back pain although other work factors like posture and manual handling can also contribute to back problems.

Occupational Health will notify Line Managers if an employee is diagnosed with a vibration related condition. Line Managers will arrange a meeting between the employee and Occupational Health. An Occupational Health professional will explain the significance of the diagnosis and provide advice on the risks form continued vibration exposure.

Employees diagnosed as having a medical condition will have a personal exposure limit applied to eliminate or restrict their exposure to vibration. Any employee referred for a Tier 4 Assessment will also have a temporary personal exposure limit applied until a diagnosis is made.

To ensure employees don't exceed their personal exposure limit their Line Manager will review the relevant risk assessment(s) and implement a set of management controls specific to that employee. The Line Manager will consult with the Employee, Health, Safety and Wellbeing Team and Occupational Health to develop these controls. The risk assessment review should also take account of the impact of any controls to the workload(s) of co-workers to ensure their own vibration exposure doesn't significantly increase.

Unit Managers will ensure a process is in place to record the health surveillance findings and any additional controls applied.

If an employee's diagnosed condition affects their ability to carry out their normal work activities, redeployment in line with the Capability Policy may be considered. The Line Manager should seek advice from HR and arrange to meet with the employee to discuss the issues and options available.

- Downloads

-

Capability Policy

DOCX file, 174.3 KB

Regular health surveillance process

Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 (RIDDOR)

There are two conditions arising from the effects of vibration that are reportable to the Health and Safety Executive under RIDDOR:

Line Managers will notify the Health, Safety and Wellbeing Team if an employee is diagnosed with one of these conditions.

The Health, Safety & Wellbeing Team will notify the HSE as soon as they have been notified of the diagnosis.